Universal Steel Beams in Oldham

STEEL PRODUCTS – EXTENSIVE STOCK, OLDHAM

James Dunkerley Steels offers finest quality steel products in Oldham. Same day/next day delivery. CE Marking BS EN 1090. New and reusable steel available.

Call now to know about our offerings.

An Introduction to Quality Steel from James Dunkerley Steels Limited

When it comes to the backbone of British construction and engineering, few names carry as much weight and history as James Dunkerley Steels Limited. Based in Oldham, we have spent decades establishing ourselves as a premier supplier of quality steel products, serving a diverse range of industries across the UK. Our commitment is simple: to provide the structural foundation for your projects through a combination of extensive stockholdings and unrivalled expertise.

A Comprehensive Range of Structural Solutions

At our Oldham facility, we maintain a vast and varied inventory designed to meet the demands of both small-scale local builders and major national infrastructure projects. We understand that every steel fabrication project is unique, which is why we supply everything from standard lengths to custom-processed steel. Our core product range includes:

-

Universal Steel Beams and Columns: The essential components for structural frameworks.

-

Channels and Angles: Versatile sections for bracing, lintels, and general fabrication.

-

Hollow Sections: Including square, rectangular, and circular profiles for aesthetic and structural applications.

-

Steel Plates and Sheets: Available in various grades and thicknesses for industrial use.

-

Quality and Service You Can Trust

Quality is the standard at James Dunkerley Steels, not an afterthought. Every piece of steel that leaves our warehouse is sourced from reputable mills and meets stringent British and European standards for strength and durability. However, we provide more than just raw materials; we provide solutions.

Our team in Oldham is equipped with advanced sawing and processing machinery, allowing us to deliver steel cut to your exact specifications, ready for immediate use on-site. Combined with our dedicated delivery fleet, we ensure that your materials arrive exactly when and where you need them. Whether you are just starting a design or are ready to break ground, we invite you to discover the reliability and personal service that defines James Dunkerley Steels.

Connect With Our Oldham Team

Are you planning your next project or looking for a reliable steel partner? Contact James Dunkerley Steels Limited today to discuss your requirements or to receive a competitive quote from our experienced sales team.

UNIVERSAL STEEL RSJ BEAMS

Dedicated to the local steel using community and serving everyone from private individuals with one off requirements to general builders, engineers and fabricators throughout the entire North West and Yorkshire regions.

Open from 8.00am until 4.30pm Monday to Friday, our sales team are here to help and await your call.

Our ‘off the shelf’ service allows customers to call in, order, pay for and collect their requirements in one short visit. Alternatively, materials can be delivered to site on a pre-arranged day.

For the more complex of requirements, technical drawings can be hand delivered, emailed or faxed prior to quotation. When final details have been agreed, our fabrication department will carry out the required work before final collection/delivery.

Please note we accept all major credit cards.

ABOUT UNIVERSAL BEAMS

Strong, versatile, and resilient – it’s no surprise that steel is one of the most widely used construction materials in the world. The construction industry accounts for more than 50% of the global steel demand and its versatility lends itself to a range of applications.

RSJ beams are renowned for their ability to maintain structural integrity and provide support across various construction projects. But to use universal beams as effectively as possible, you’ve got to learn all about them. Let’s explore them in greater detail.

WHAT IS A UNIVERSAL BEAM?

Also referred to as a UB or universal steel beam, universal beams are robust, structural steel shapes typically used for large-scale building projects. You can think of RSJ beams as the skeletal structures of a building, or the stabilising supports in bridges, roofs, or floors.

There are a wide range of universal beams sizes, making them incredibly versatile; plus, their dimensions are standardised, which helps promote greater consistency and ease of use during the construction process. Generally, universal steel beams will have an I or H shape when viewed from the side.

Without an integral structure and sturdy foundation, you are likely to encounter some serious difficulties in the future. From decreased longevity to operational issues, securing the highest quality steel RSJ beams is essential. Finding the right RSJ suppliers near me is the first step towards ensuring an exceptional and reliable use of universal steel beams.

WHAT DO UC AND UB MEAN IN BEAMS?

UB stands for Universal Beams whereas UC stands for Universal Columns. Both UB and UC are structural steel shapes used to provide support and stability in a wide range of construction and engineering projects. However, there are some notable differences between the two.

Universal Columns are long and slender, allowing them to support heavy loads in a vertical orientation. Their rectangular cross-section provides the necessary strength to avoid any twisting as they support the downward weight of the structure above them. UCs are often used as vertical support columns in building frames or foundations.

Contrastingly, Universal Beams are broad and flat, which helps them support heavy loads in a horizontal orientation. Their wide flange increases the load-carrying capacity while simultaneously increasing its ability to withstand deflection and bending. This sturdy shape provides plenty of stability and helps sustain extremely heavy loads. RSJ beams are vital components of building frames and are commonly used to support roof or floor structures.

WHAT ARE THE 5 TYPES OF UNIVERSAL BEAMS?

Universal beams are classified by their shapes, sizes, and how they’re attached to the structure of the building. The universal beams sizes and types you need will vary according to the specifications of your construction project.

If you’re looking for RSJ for sale, learning how to differentiate between the different RSJ sizes and prices is vital. Here is a closer look at the five most common types of universal steel beams.

SIMPLY SUPPORTED

Simply supported beams are steel RSJ beams that are free to move horizontally and rest with two supports (one at either end). One end of the beam has a pinned or hinged support, while the other end of the beam has a roller support, allowing the beam to rotate or pivot. There are no additional points of support in between. These RSJ beams are typically used as bridge girders or roof and floor beams.

FIXED

As the name suggests, fixed steel RSJ beams are those that are welded or bolted into place. Since the supports are fixed in place, these types of universal steel beams cannot rotate vertically or horizontally. Instead, these RSJ beams are designed to provide a rigid support that prevents deflection. Fixed universal steel beams can be found in overhead cranes, structures along roadways, and as additional support for tall buildings or stadium roofs.

CONTINUOUS

Continuous steel RSJ beams are those that feature a string of multiple supports across the beam. One way to visualise continuous RSJ beams is to imagine a single beam supported by a series of columns along its length. These are often used when longer spans with even distribution are required. Continuous RSJ beams are employed in multi-span bridges, large industrial warehouses, and high-rise buildings.

OVERHANGING

Overhanging beams have one or both end portions extend further than the supporting structures. Typically, overhanging beams feature a hinge support or a roller support. One of the most common uses for overhanging RSJ beams is the creation of balconies that extend beyond the building’s main structure.

CANTILEVER

Cantilever beams are constrained with a fixed support on one end and extended freely on the other. The fixed support works to prevent horizontal movement and rotation whereas the free end can carry loads and support design functions such as balconies, overhangs, or diving platforms.

WHAT IS THE STRONGEST STRUCTURAL BEAM?

The strongest structural RSJ for sale must be the I-beam. They are a staple in the construction of large-scale projects and their versatility is widely recognized in the steel structure industry.

The I-beam’s name is derived from its shape, which resembles an I. This steel structure features broad horizontal flanges on both the top and bottom, as well as a central vertical web. When viewed from the side, the cross-sectional shape appears as an I.

The wider flanges of the I-beam help improve the inertia of the beam, which contributes to a greater load-carrying capacity. Similarly, the broad characteristics of the I-beam ensure a more even distribution of weight across the length of the beam and enhanced stability. It also provides ample surface area to help forge a connection with other structural elements.

I-beams are considered the strongest universal steel beams because they can resist buckling under pressure and withstand extreme lateral forces such as high winds or earthquakes. Beams in this position should bend rather than buckle as they carry large loads. Buckling exerts additional tension and can compromise the stability and safety of the structure. Overall, the I-beam is the optimal choice for its versatility and high load bearing capacity.

UNIVERSAL STEEL COLUMNS

Universal columns are similar in appearance to universal beams, but typically have a wider flange or fillet.

Universal columns are structural steel columns used in a vertical position. Their I-shaped cross-section is similar to that of universal beams, but a steel column flange is usually wider than that of a beam.

There are several elements that combine to define universal column sizes. This includes the depth and width of the steel section, the thickness of its web and flanges, the root radius and the depth between the fillets.

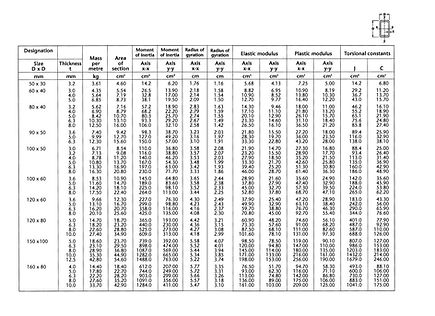

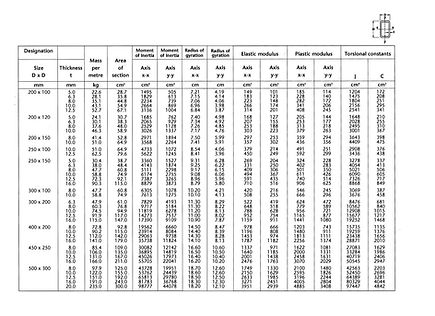

For full details of all the universal column sizes we supply, please consult our universal column table, which specifies characteristics like plastic modulus, elastic modulus, torsional index and more.

WHAT IS A STEEL COLUMN?

A steel support column is normally positioned vertically, for example to reinforce a concrete pillar, or to support a ceiling or upper storey.

The cross-section of universal columns is shaped like a capital I or H, with several key characteristics:

-

The central span of the cross-section is the web

-

Each of the four ‘wings’ at right-angles to this span is a flange

-

Each pair of flanges (forming a T-shape with the web) is a fillet

Knowing these basic 2-3 elements gives rise to a number of parameters when specifying universal steel columns:

-

h is the depth of the section (the full height of the I-shape including the fillets)

-

b is the width of the section (the full width across the tips of the flanges)

-

s is the thickness of the web (the central span that connects the fillets)

-

t is the thickness of the flanges (measured across the flat section of the flange)

-

r is the root radius (the inner curve of the right angle where the flanges join the web)

-

d is the depth between fillets (the depth of the section minus the thickness of the flanges)

All of these parameters come into play when calculating universal column sizes. Our handy universal column table shows what’s available, along with some practical values like the cross-sectional area and the mass per metre.

HOW THICK DO STEEL COLUMNS NEED TO BE?

The ‘thickness’ of a steel column can be defined in various ways, such as the thickness of the web and fillets, the width or depth of the section, and even the effect of the root radius.

Because of this, calculating exactly how thick steel columns need to be depends on the specific application for which the universal column will be used.

In general, a larger cross-sectional area (referred to as the ‘footprint’ of the steel column) is associated with thicker web and fillets, and will therefore lead to a higher mass per metre and greater strength.

Our structural steel columns range in size from 152.4 x 152.2 mm and a mass of 23.0 kg per metre, up to 474.6 x 424.0 mm and a mass of 633.9 kg per metre.

WHAT SIZE ARE STRUCTURAL STEEL COLUMNS?

The footprint of the column dictates its size in terms of the area of land it will occupy. Because structural steel columns are typically perfectly vertical, the column will usually stand perfectly over this footprint, without taking up any more space.

Combined with the recesses between the fillets and the web, this can give universal steel columns a surprisingly minimal profile in use, even when installed as a free-standing column to support a platform or mezzanine.

In many cases, structural steel columns are used purposefully as part of an industrial interior design scheme, with the intention of being left visible, rather than being boxed in or otherwise disguised.

The height of the column (that is, the measurement perpendicular to the cross-sectional area) will depend on what the column is supporting, and will have a direct impact on the total weight of the steel section.

Calculating the total weight is simply a case of determining the height of the column and multiplying by the specified mass per metre, to give a total mass in kg.

Again, all of these characteristics can be found in our downloadable steel column table, providing a handy guide to calculate mass and footprint, and as a reference when placing an order.

ARE STEEL COLUMNS STRONGER THAN CONCRETE?

Structural steel columns are very strong. As an alloy, steel is much stronger than the iron from which it is made, and the shape of a universal column’s cross-section helps to reinforce it against bending and warping.

For a load-bearing column, compressive strength is important. Steel columns can typically withstand loads of around 36,000 psi (250 MPa).

In contrast, concrete alone is relatively weak under compression forces, at around 4,000 psi (27.5 kPa). That is unless it is reinforced – which is normally done using steel.

Recycled steel suffers no loss in quality, allowing recycled steel columns to provide just as much strength as those made of virgin steel.

Because of this, steel is a truly sustainable construction material – allowing strong structures to be built time and time again, versus concrete which is essentially a single-use mineral for such applications.

STEEL CHANNELS

Steel channels are broadly speaking C-shaped (or U-shaped) sections of steel, with a flat side and two flanges facing on to an open side.

Although the term ‘channel’ may sound like the section is intended to be used in a U-shaped configuration, for example to carry an open stream of water, in practice these are generally thought of as C-shaped sections.

This means that the ‘depth’ of the channel is actually given as the distance across the flat side, or between the flanges if they are parallel.

The ‘width’ of the section relates to the distance across the flange, from the corner where it attaches to the flat side of the channel, to its open opposite edge.

And certain other measurements – such as the thickness of the metal used – dictate the mass per metre of the section, which is typically quoted as its third dimension.

As such, a steel channel might range from ‘100 x 50 x 10’ – a closed side of 100mm, flanges of 50mm and a mass per metre of around 10kg – to ‘430 x 100 x 64’.

Note the different units used – whereas the first two dimensions are in mm, the third is in kg per metre.

Together, these should allow the desired size to be specified for any project with a good degree of accuracy. For more information about the supply of steel channels, contact James Dunkerley today.

C-SHAPED STEEL CHANNELS

C-SHAPED CHANNELS

C-channel steel is a shape of steel section with a C-shaped cross-section, given by a vertical web and two horizontal parallel flanges that extend to only one side of the web.

The result is a shape similar to a capital letter C, but with 90-degree corners where the flanges meet the web.

Steel C-channel is often used where the design needs the steel section to have one completely flat side, for example where the web is welded to a wall or other flat surface.

Two steel C-channels can also be welded back to back, although it’s more common to specify I-shaped channel for this purpose.

OTHER NAMES FOR C-CHANNEL STEEL

C-channel stainless steel is also referred to using several alternative names:

-

U-channel steel

-

Parallel flange channel steel (PFC steel)

-

Structural channel steel

When ordering steel C-channel, the dimensions of the web and flanges are used to specify the size needed (see below).

WHAT IS A C-CHANNEL?

Aside from its overall shape, C-channel stainless steel is specified using several measurements:

-

Depth of section (h)

-

Width of section (b)

-

Thickness of web (s)

-

Thickness of flange (t)

-

Depth between fillets (d)

-

Root radius (r)

C-channel steel is designated using the depth and width of the section, and its mass per metre. For example, steel C-channel 430mm tall, 100mm wide and 64.4 kg per metre is designated as 430 x 100 x 64.

You can see a full list of our C-channel steel, ranging from 430 x 100 x 64 down to 100 x 50 x 10, on our website and in our downloadable PDF.

USES FOR STEEL C-CHANNELS

As a steel channel with an inner recess, C-channel steel can be used as a conduit, e.g. to protect pipes or cables, in addition to its general structural applications.

Laid horizontally on its web, U-channel steel can also carry water and other fluids, or be used to create a run-off channel for spillages.

Because the flanges are only on one side of the web, steel C-channel is not as structurally strong as, for example, I-channel steel with flanges on both sides.

However, when welded against a wall or surface, the flat-back profile of C-channel stainless steel means it can be used to create strong wall-mounted rails and similar features, where I-shaped steel would be impossible to mount flush to the surface.

TO PLACE YOUR ORDER

Contact James Dunkerley Steels Limited today to place your order for C-channel steel from our available stock.

You can see detailed parameters (e.g. elastic and plastic modulus, buckling parameter and torsional index) for our full range of C-shaped steel sections on our PDF data sheet.

If you’re not sure what size you need, or you want to check the strength of a specific size under different forces, just ask and our team will be happy to help.

For any other help with C-shaped steel sections, or any of our structural steel and sectional steel range, you can contact James Dunkerley Steels Limited on 0161 624 3168 or email us at sales@dunkerley.co.uk.

SQUARE / RECTANGULAR STEEL BOX SECTIONS

Square and rectangular steel box sections are lengths of hollow box section steel with a rectangular profile, curved corners and a hollow centre. They are some of the most versatile mild steel box sections, with applications ranging from cabinet making and light fabrication, through to their use as pipes and conduits. James Dunkerley Steels supply rectangular box section steel in a range of cross-sectional sizes and thicknesses, to suit a highly diverse variety of applications.

Of course, a square is simply a rectangle whose sides are all the same length, but for simplicity’s sake they tend to be listed as a separate product category entirely.

STEEL BOX SECTION SIZES

Our square hollow sections steel dimensions begin at a size of 40mm x 40mm and a thickness of 3.0mm, and go up to a maximum of 400mm x 400mm and 20.0mm thick.

The width measurement is the outer dimension, while the thickness of the steel will determine the size of the inner dimension of the cavity itself.

Where the size of the inner cavity is significant, the width specified should therefore be based on the minimum acceptable cavity size, with the thickness of the steel added to this twice, once for each parallel side of the square.

Rectangular hollow section sizes start from 50mm x 30mm and 3.2mm thick, although some larger sizes can be specified at 3.0mm thick.

Our largest standard size for rectangular steel box sections is 500mm x 300mm and 20.0mm thick.

Steel box section sizes are usually specified as width x height in mm. For a rectangular box section these will be different dimensions; for a square box section they will be the same. A third parameter is also specified: the thickness of the steel.

The thickness of the walls influences the strength of rectangular box section steel, but also the weight, so it’s important to take both into account when ordering.

Find full details in our downloadable PDF technical data sheets, or just ask and we’ll be happy to help you decide what size of square or rectangular box section you need.

STEEL FLAT BARS

Mild steel flat bars are one of the most popular styles of steel products due to their versatility and durability. They can be used both structurally and decoratively in a wide range of domestic and commercial applications.

Steel flat bars are found in almost every industry because they are easy to cut, weld, and bend to suit any particular shape. You just as easily can find them in the chassis of cars as you can in the frames of bridges.

FLAT BARS SIZES AND FINISHES

For easier application, we stock a wide range of flat bar sizes, from 13mm x 3mm all the way up to 150mm x 6mm. We also offer smaller widths with thicknesses of up to 50mm.

We understand that every client has a set of unique needs. That’s why we’ve ensured our mild steel flat bars span from ultra-thin sections to robust cross-sections similar to our solid square bars.

If you need specific measurements for your projects, we can arrange this for you. We can cut and drill steel flat bars as required, so let us know if this could be of use.

Ultimately, the width and thickness of the bar will affect the direct bearing weight of the mild steel product. For example, our smaller thinner bars may only hold around 10 kg per metre whereas our largest bars can withstand up to 100 kg per metre.

We also offer finishing work, such as painting or galvanising, so you won’t have to worry about doing this on-site. Simply inform us of your desired finish and timeline constraints to ensure a speedy delivery.

Our in-house fabrication team are able to work with flat steel to fabricate light assemblies ahead of delivery, whatever your specific needs may be.

Any and all such enquiries are welcome, and we can also carry out other finishing work on flat bars, such as painting or galvanising them, so that this does not need to be done on site.

Like our other steel products, we can also cut and drill flat bars as required, so again simply let us know if this is something you need us to do.

ORDER STEEL FLAT BARS TODAY

If you’re in need of premium steel flat bars, look no further than James Dunkerely. We can offer made-to-measure solutions for a wide range of steel applications.

Our in-house fabrication team is at your disposal. We can fabricate light assemblies ahead of deliveries and accommodate any bespoke requirements – whatever they may be.

Don’t hesitate to contact us if you have any questions or would like to make an order. Our team is fully prepared to offer expert guidance and assist you every step of the way.

ROUND / SQUARE SOLID STEEL

Solid ’rounds’ (AKA circles) and squares of steel have their own applications, and their solid construction can make them a very reliable alternative to hollow pipes or box sections.

WHAT IS A STEEL ROUND?

Steel rounds are known for having circular cross-sections and a range of industrial applications. Also referred to as a solid steel rod, these versatile products are known for their strength, malleability, and durability.

They provide a reliable alternative to hollow steel sections while enhancing the structural integrity of your project; however, this extra strength comes with additional weight. Unlike hollow sections, solid bars rapidly accumulate mass as sizes increase.

For example, 16 metres of steel rounds with a 100mm diameter equates to a tonne of steel. Therefore, you must carefully assess your needs and select the most suitable size for your requirements.

Because they are solid, these round and square bars can become very heavy very quickly, and as such their size is typically no larger than around 100mm.

At the largest size, this equates to a mass of 61.60kg per metre, and just 16 metres will therefore weigh one tonne.

For less heavy-duty applications, smaller cross-sectional areas can be specified, and the smallest measures in at 6mm, equivalent to 0.22kg per metre.

This allows for more than 4,500 metres of bar to be used before one tonne of weight is added to the project site.

As with other products, solid rounds and squares can be worked upon before delivery by our Services and light fabrication team.

Where necessary, they can be painted or galvanised, to give them the desired appearance or to protect the surface of the steel against exposure to the weather, abrasion or other potentially harmful processes and substances.

There are more than 15 different sizes to choose from, subject to availability – allowing solid rounds or squares to be specified that closely match the demands of your project.

WHAT ARE ROUND STEEL BARS USED FOR?

You can find many uses for a solid steel rod, and they’re often seen in industries such as construction, manufacturing, shipbuilding, and transportation. They can provide additional support in structural projects or even be used to create machine parts like shafts and axles.

Steel rounds offer a great deal of high tensile strength which allows them to resist deformation under stress and withstand heavy loads. Similarly, they can be flattered or shaped into various forms without fracturing which makes them useful in a range of applications.

Lastly, steel bars are highly durable and resistant to wear, corrosion, and abrasion. This durability ensures long-term performance and reduces the need for frequent maintenance or replacement.

All in all, the combination of properties makes steel rounds a highly sought-after and indispensable product across various industries.

WHAT SIZE IS A STANDARD STEEL ROUND BAR?

We stock 16 sizing options, with our smallest cross-section starting at 6mm and the largest model reaching 100mm. For a more in-depth look at sizing and weight options, please examine the table below:

ORDER STEEL ROUNDS TODAY

If you’re looking for premium steel rounds, James Dunkerely stocks a wide range of sizes to keep your project running as smoothly. We offer made-to-measure solutions and painting services for all kinds of steel applications.

Our in-house fabrication team is at your disposal. We can fabricate light assemblies ahead of deliveries and accommodate any bespoke requirements – whatever they may be.

Don’t hesitate to contact us if you have any questions about steel rounds or would like to make an order. Our team is fully prepared to offer expert guidance and assist you every step of the way.

STEEL ANGLES

Steel angles are L-shaped sections with plenty of uses, the main ones of which are typically constructional.

It is easy to work with and relatively easy to cut, as well as to weld, and all of this makes it a popular format for steel for the construction industry.

Angle steel may particularly be seen in the construction of frames and racks, as well as any other application for which it is suited.

When specifying angle steel, there are two main options: equal angles and unequal angles.

This is actually not to do with the size of the angle between the two sides, which is fixed at 90 degrees; instead, it relates to the ratio of the length of the two sides.

In an equal steel angle, the sides – think of them as the two strokes of a capital letter L – are of equal size, hence the name.

Equal steel angles start from 40mm x 40mm and range up as far as 200mm x 200mm, in a range of thicknesses from 4mm to 24mm.

Unequal steel angles have two different measurements for the sides, ranging from 65mm x 50mm to 200mm x 150mm.

The ratio between the two may vary, and again a variety of thicknesses are available to suit different applications.

STEEL TUBING & STEEL PIPES

Steel pipes and tubes are strong, versatile metal components with a vast range of applications and an equally broad range of sizes and specifications.

They may be used to carry fluids, or as highly protective outer casings for cables and other such connections that require an impervious conduit.

Tubular steel sections may also be used in temporary structures, such as scaffolding, to provide reliable vertical support without the risk of buckling.

And by virtue of being hollow, steel pipes and tubes can often achieve this with less total weight than a solid steel section would carry.

Our range of steel pipes and tubes begins from an outer diameter of just 21.3mm and scales up to a maximum of 457.0mm, with more than 15 other sizes to choose from in between.

Each size also offers a selection of thicknesses, except for our smallest sizes which are supplied at a thickness of 3.2mm.

The diameter and thickness together determine the total weight per unit length of the tube, which may be critical in certain applications.

A 21.3mm tube with a thickness of 3.2mm is our lightest option at 1.43kg per metre length, while at the top end of the scale, a 457.0mm tube 40.0mm thick weighs in at 411.0kg per metre.

ROAD PLATES MADE FROM STEEL

Steel road plates are a product from James Dunkerley Steels Limited’s Plates division, and are one of our biggest-selling product lines.

We have a broad range of different sizes of steel road plates in stock, already cut and holed, and ready for immediate use on site.

They can be used to create a strong surface over which pedestrians and heavy machinery can pass, increasing safety on sites with open trenches in the roadway.

For long trenches or where multiple trenches cross one another, several steel road plates can be placed to safely cover the area without gaps.

The thickness of the plates can vary, from thin quarter-inch (6mm) plates for fairly light applications, to two-inch (50mm) plates for the most heavy-duty of purposes.

Similarly, the surface area of steel road plates can vary considerably, with our most popular sizes being 6′ x 4′ and 8′ x 4′ – we have these cut and holed ready for use, but can also supply other sizes as needed.

These include very large sizes, up to and including inch-thick plates measuring 12′ x 6′.

Our largest plates weigh in at over 1,300kg, while a quarter-inch 6′ x 4′ plate weighs just over 100kg, highlighting the breadth of choice available.

FIND THE RIGHT STEEL FOR YOUR PROJECT TODAY

Looking for reliable steel products that match your requirements? Contact us now to get expert advice and the quality you can trust.